-

GuillermoExcellent! Fast delivery! I like to work with you again!

GuillermoExcellent! Fast delivery! I like to work with you again! -

Perus ColetteIt is my pleasure to do the business with LiFong,they always do the best for us.

Perus ColetteIt is my pleasure to do the business with LiFong,they always do the best for us. -

Robin SeifertI like the products and service provided by LiFong. They really take our interest into consideration.

Robin SeifertI like the products and service provided by LiFong. They really take our interest into consideration. -

SjakThat's true we enjoy doing business with you.

SjakThat's true we enjoy doing business with you. -

Kelly MarshLiFong is one of our desired vendors in China

Kelly MarshLiFong is one of our desired vendors in China -

رایموند شنککیفیت محصول، قیمت های رقابتی، همیشه یکی از تامین کنندگان کلیدی ماست

رایموند شنککیفیت محصول، قیمت های رقابتی، همیشه یکی از تامین کنندگان کلیدی ماست

برنج با دقت و اتصالات آب ریخته گری و براکت را از دست داد

| Place of Origin | Guangdong, Mainland China |

|---|---|

| نام تجاری | LF |

| گواهی | ISO9001:2008, TS16949 |

| Model Number | LF-DJ1110 |

| Minimum Order Quantity | 1000 PCS |

| قیمت | negotiable |

| Packaging Details | Part in Bubble Bag, then in Cartons, Wooden Pallet on Bottom, Film wrapped overall then Nylon belt fastened Or to be Customized Means of Packing. |

| Delivery Time | MOQ 1 Week, 30,000pcs+ : 4 Weeks. |

| Payment Terms | TT, L/C |

| Supply Ability | 150,000 PCS Per Month |

| ماده | برنج | اثبات | ریخته گری موم |

|---|---|---|---|

| برجسته کردن | ,,led lighting housing |

||

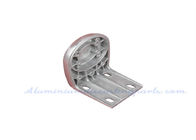

Powder Coated Aluminum Pressure Die Casting Bracket of Curtain Rotation Shaft

Quick Details:

Precision Aluminum die casting & Aluminum casting

Large Image: Aluminum Bracket of Curtain Rotation Shaft, Spin Axis and Revolving Shaft.

Suface Treatment: Polish/Sanding Blasting/Brush Finish+ Powder Coating

Depend on customer's requirements

Description:

Large Image: Curtain Spiale Bracket

Bracket of Curtain Rotation Shaft

Bracket of Curtain Spin Axis

Bracket of Curtain Revolving Shaft

Application: Curtain Spiale

Specification:

| Overall Dimension | L200*W150*H150mm |

| Surface Treatment | Polish/Sanding Blasting/Brush Finish+ Powder Coating |

| Part Weight | 400 Grams |

| Material | ADC12 (Standard: JIS H 5302-2000) ; America : 383 (Standard: ASTM B 85-03 Standard ) |

Facility:

![]()

Die Casting Workshop

![]()

200 Ton Die Casting Machine

![]()

Machining Workshop

Processing Technic:

1. Die Casting Tooling Making--Prototype/T1--Dimension Check-- Sample Approval-- SOP

2. Die Casting-- Deburring-- Dilling Holes/ Threading-- Polishing-- Sand Blasting-- Quality

Check (dimension and surface) -- Oil Painting -- QC (Surface Vision Checking)-- Packing

Advantages:

1. Professional Research and Design Team (20 Persons), Possess All Necessary Equipments.

2. Strict Quality Control in Each Process and Finish Product Quality Control

3. Short Delivery Lead Time: 15-30 Days

4. Optional For OEM or ODM

5. Comprehensive After-Sale Service, Quick Responses For Daily Communication