-

GuillermoExcellent! Fast delivery! I like to work with you again!

GuillermoExcellent! Fast delivery! I like to work with you again! -

Perus ColetteIt is my pleasure to do the business with LiFong,they always do the best for us.

Perus ColetteIt is my pleasure to do the business with LiFong,they always do the best for us. -

Robin SeifertI like the products and service provided by LiFong. They really take our interest into consideration.

Robin SeifertI like the products and service provided by LiFong. They really take our interest into consideration.

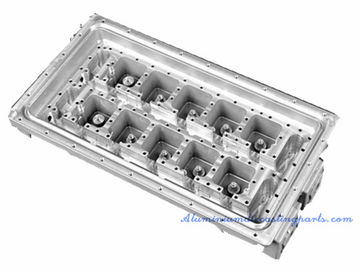

Sand Blasting High Pressure Die Casting Heat Sink For Electrical Cabinet

| محل منبع | GuangDong,Mainland China |

|---|---|

| نام تجاری | LF |

| گواهی | ISO9001:2008,TS16949 |

| شماره مدل | LF-DJ0177 |

| مقدار حداقل تعداد سفارش | 500 PCS |

| قیمت | Negotiable |

| جزئیات بسته بندی | Part in Bubble Bag, then in Cartons, Wooden Pallet on Bottom, Film wrapped overall then Nylon belt fastened Or to be Customized Means of Packing. |

| زمان تحویل | MOQ 2 Weeks, 10,000pcs+ : 4 Weeks. |

| شرایط پرداخت | TT,L/C |

| قابلیت ارائه | 30,000 PCS Per Month |

برای نمونه و کوپن رایگان با من تماس بگیرید.

واتساپ:0086 18588475571

وی چت: 0086 18588475571

اسکایپ: sales10@aixton.com

اگر نگرانی دارید، ما به صورت آنلاین 24 ساعته راهنمایی می کنیم.

x| برجسته | ,,high pressure die casting |

||

|---|---|---|---|

Sand Blasting High Pressure Die Casting Heat Sink For Electrical Cabinet

Quick Details:

Precision Aluminum die casting & Aluminum casting

Large Image: Aluminum Heat Sink For Electronic Device

Surface Treatment: Sand Blasting

Depend on customer's requirements

Description:

Large Image: Aluminum Heat Sink For Electronic Device

Copper Pipe Heat Sink Electrical Device

Cast Copper Pipe Heat Sink

Die Casting Heat Sink with Copper Pipe Embodied

Application:

Cooling For Electronic Device

Specification:

| Overall Dimension | L300*W150*H11mm |

| Surface Treatment | Sand Blasting |

| Part Weight | 0.2 kgs |

| Material | A380 (Standard: ASTM B 85-03 Standard ) |

Processing Technic:

1. Die Casting Tooling Making--Prototype/T1--Dimension Check-- Sample Approval-- SOP

2. Die Casting-- Remove Water Gap--Deburring-- Machining--Dilling Holes/ Threading-- Quality Check (dimension and surface) ---QC (Surface Vision Checking)-- Packing

No Surface Treatment Requested

Advantages:

1. Professional Research and Design Team (20 Persons), Possess All Necessary Equipments.

2. Strict Quality Control in Each Process and Finish Product Quality Control

3. Short Delivery Lead Time: 15-30 Days

4. Optional For OEM or ODM

5. Comprehensive After-Sale Service, Quick Responses For Daily Communication